Research on hydraulic fracturing gas extraction technology for No.15 coal seam of Wulihou Coal Mine

-

摘要:

针对五里堠煤矿15号低渗透性煤层常规预抽孔存在的钻孔密集、投入成本高、抽采效率低、抽采周期长等问题,开展了顺层钻孔水压致裂瓦斯抽采技术研究。现场试验结果表明:2101工作面最大主应力为水平应力,应力值为18.3 MPa,方向角为N31.65°E,中间主应力为垂直应力,产生的压裂裂缝沿最大主应力方向,裂缝形态以垂直裂缝为主;煤层起裂压力为25~29 MPa,压裂影响半径为5~8 m;压裂后4个月累计抽采瓦斯量约为1.8×10 4 m 3,吨煤瓦斯含量从原始10.85 m 3/t降低至2.63 m 3/t,压裂抽采效果显著。采用压裂抽采工艺后,钻孔工程量减少了1/2,抽采瓦斯周期缩短2~3个月,显著提高了煤矿经济效益,对掘进工作面的快速掘进施工亦有重要借鉴意义。

Abstract:Aiming at the problems existing in conventional pre-extraction holes in No.15 coal seam with low permeability of Wulihou Coal Mine, such as intensive drilling, high cost, low extraction efficiency and long extraction period, etc., the research on hydraulic fracturing gas extraction technology of drilling along the layer was carried out. The field test results show that the maximum principal stress of 2101 working face is horizontal stress, the stress value is 18.3 MPa, and the direction angle is N31.65°E, and the middle principal stress is the vertical stress. The fracture generated is along the maximum principal stress direction, and the fracture morphology is dominated by the vertical fracture position. The fracture initiation pressure of coal seam is about 25 MPa to 29 MPa, and the fracturing influence radius is about 5 m to 8 m. Four months after fracturing, the cumulative amount of gas extracted is about 1.8×10 4 m 3, and the gas content per ton of coal decreases from the original 10.85 m 3/t to 2.63 m 3/t, indicating a significant effect of fracturing and extraction. The drilling quantity is reduced by half, the gas extraction period is shortened by 2 months to 3 months, and the economic benefit of coal mine is significantly improved after fracturing extraction technology is adopted. It also has important reference significance for the rapid tunneling construction of driving face.

-

随着煤矿开采深度的增加、大型机械化生产能力的提升,煤岩地应力增高、渗透率降低,瓦斯含量和压力相应升高,高瓦斯和突出煤矿日益增多,瓦斯灾害日趋严重。瓦斯突出严重影响和制约了煤矿安全生产 [ 1- 4] ,治理煤矿瓦斯灾害仍然是当前我国煤矿安全领域中的重大技术课题 [ 5- 8] 。

井下预抽煤层瓦斯受到诸多局限,煤层透气性是影响煤层瓦斯预抽效果的决定性因素。国内95%的高瓦斯和煤与瓦斯突出矿井的煤层透气性系数约为0.04~0.004 m 2/(MPa 2 · d),远小于0.1 m 2/(MPa 2 · d) 的可抽采要求 [ 9- 12] ,瓦斯预抽效果差。同时,传统的本煤层瓦斯抽采工艺,钻孔密集,施工强度大,抽采周期长,不利于矿井采掘衔接,技术工艺有待进一步改进。

国内外实践证明,通过压裂技术手段配合抽采方式将煤层中赋存的瓦斯开采出来,不仅可以降低煤层瓦斯含量,预防瓦斯突出,还可为社会提供丰富的洁净能源。

自美国KANSAS第一次水压致裂试验成功后,历经70余年的发展,水压致裂技术从理论到应用都取得了丰硕的成果,成为石油、天然气、非常规天然气等油气井增渗的有效技术措施 [ 13- 15] 。GIDLEY [ 16] 、MURDONCH [ 17] 、邓广哲 [ 18] 、黄炳香 [ 19] 、雷毅 [ 20] 等都曾对水压致裂技术的发展进行了总结与研究。近几年,水压致裂治理区域瓦斯抽采技术逐渐在全国的地下煤矿试验并得到推广 [ 21- 23] 。

笔者针对沁水煤田北部五里堠煤矿15号煤层瓦斯含量高、渗透性差、抽采周期长等制约煤矿安全生产的问题,开展了本煤层压裂抽采技术研究。

1. 矿井概况

五里堠煤矿井田位于山西省左权县境内、沁水煤田北部, 矿井井田面积9.860 2 km 2。矿井批准开采3~15号煤层,现开采15号煤层,核定生产能力120万t/a。

15号煤层采用走向长壁综采放顶煤工艺,其2101工作面长度约200 m,煤层平均厚度约6.17 m,赋存稳定;煤层顶板为砂质泥岩,底板为泥岩,煤层倾角为8°~18°。煤层绝对瓦斯涌出量为18.26 m 3/min,相对瓦斯涌出量为10.85 m 3/t,瓦斯压力最大为0.46 MPa,属于高瓦斯矿井。

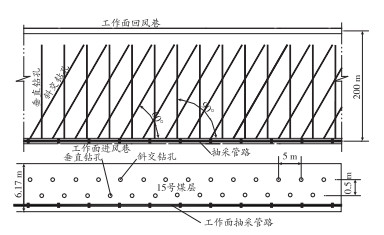

15号煤层瓦斯抽采属性介于可以抽采和较难抽采之间,需要采用一定的强化抽采方法才能取得预期抽采效果。现有的抽采设计方案为在15号煤层回采工作面内,利用垂直和斜交于工作面进风巷向煤层施工的加密交叉钻孔对工作面煤层进行预抽。利用钻孔周围的应力叠加扩大塑性区的范围和连通性,增加煤体的裂隙,提高煤体透气性,预期达到提高预抽瓦斯效果的目的。加密交叉钻孔预抽回采工作面本煤层瓦斯方法的钻孔布置如 图 1所示。该瓦斯抽采方式钻孔密度大、数量多、抽采成本高、施工强度大,短期内抽采效果不佳。

针对上述问题,本项目拟采用煤层水压致裂抽采瓦斯技术对15号煤层回采工作面瓦斯进行压裂抽采试验研究,以期在降低钻孔施工量的同时提高工作面瓦斯抽采效果,实现工作面的安全高效开采。

2. 压裂钻孔方案设计

2.1 地应力测试

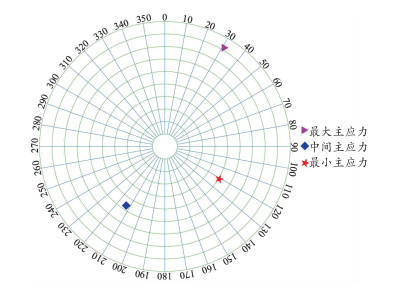

为设计水压致裂方案,针对2101工作面回风巷采用空芯包体应力解除法进行地应力测试。测孔实测的主应力分布网络如 图 2所示。

测试结果表明:弹性模量和泊松比分别为14.28 GPa和0.25;工作面最大主应力为水平应力,其值为18.3 MPa,方向角为N31.65°E;最小主应力为水平应力,均值为10.2 MPa,方向角为N121.32°E;中间主应力为垂直应力,均值为11.7 MPa,方向角为N214.95°E。测孔的地应力测试数据见 表 1。

表 1 1号测孔的地应力测试数据应力类别 应力/MPa 方向角/(°) 倾角/(°) 最大水平应力 σ 1 18.3 N31.65E 11.54 垂直应力 σ 2 11.7 N214.95E 82.57 最小水平应力 σ 3 10.2 N121.32E 15.51 2.2 压裂钻孔布置方案

15号煤层煤体强度较低,经顺煤层钻孔采样进行物理力学测试,平行层理方位单轴抗压强度为0.86~1.44 MPa,抗拉强度为0.2~0.5 MPa,视密度为1.41 t/m 3,单位质量孔隙率为8.44%,孔裂隙发育但连通性较差,单位质量煤体天然含水率约为2.3%。

根据地应力参数,确定水压致裂裂纹形态为沿最大主应力方向、垂直于煤层层理面产生垂向斜交水力裂缝,方向角为N31.65°E。

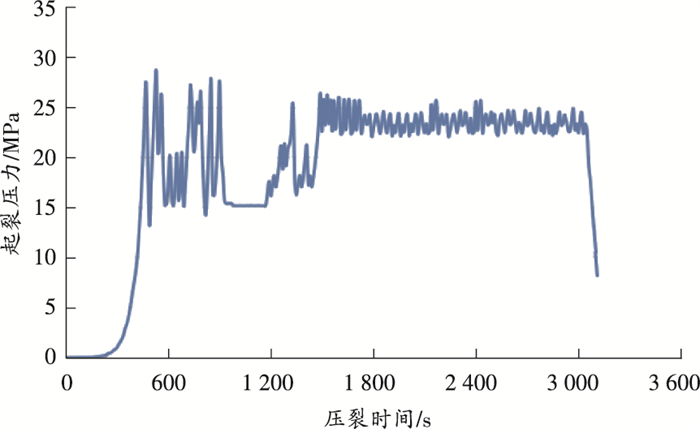

试验孔裸眼压裂参数:回风巷巷帮竖直方向约4.0 m高度布孔,孔径133 mm,顺层方向水平钻进120 m,封孔段15 m,采用清水压裂液,流量1 000 L/min。试验孔压力与压裂时间曲线如 图 3所示。

试验孔起裂压力为25~29 MPa,单孔注水量约300 t。试验孔压裂完成后,在压裂孔两侧3、5、8、10、12 m位置分别钻孔取样(深100 m)进行含水率测试,每个钻孔内间隔约20 m测定一组试样含水率(测定结果见 表 2),与原煤含水率(约2.3%)进行对比。

表 2 观测孔含水率测试数据钻孔

编号间距/

m30 m试样

含水率/%50 m试样

含水率/%70 m试样

含水率/%90 m试样

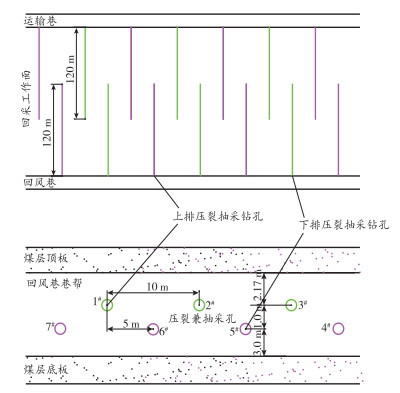

含水率/%1 # 3 6.8 7.3 6.7 7.1 2 # 5 5.7 6.2 6.1 6.3 3 # 8 4.3 3.7 4.4 4.5 4 # 10 3.2 3.0 3.5 3.3 5 # 12 2.8 2.6 3.3 2.2 从 表 2可看出,单孔压裂影响半径为5~8 m,考虑到煤体非均质及裂隙发育的复杂性,局部裂纹可能产生一定偏转,为进一步加强压裂影响效果,达到预期高效抽采目标,选择较小的影响范围,确定压裂孔间距为5.0 m。压裂抽采孔采用双排“三花眼”布置形式,顺层布置120 m孔进行压裂,具体布置参数见 图 4。

3. 压裂试验效果及分析

为检验压裂后抽采效果,对瓦斯抽采周期进行统计分析,对残存瓦斯含量进行测试对比。

该矿及周边矿井原有的15号煤层抽采瓦斯资料显示:煤层百米钻孔(单孔)初始瓦斯抽采量平均约为0.055 6 m 3/min(约80 m 3/d),其逐月累计抽采瓦斯数据见 表 3。

表 3 原设计抽采钻孔逐月累计抽采瓦斯数据汇总抽采时间/月 抽采瓦斯总量 Q t/m 3 5 17 452 6 17 813 7 18 004 采用本煤层压裂抽采工艺后,对1 #~7 #钻孔的抽采瓦斯情况进行了追踪统计,15号煤层试验段压裂后百米钻孔(单孔)初始瓦斯抽采量平均约为0.217 m 3/min,各钻孔逐月累计抽采数据汇总见 表 4。

表 4 压裂抽采钻孔逐月累计抽采数据汇总抽采孔

编号3个月累计

抽采量/m 34个月累计

抽采量/m 35个月累计

抽采量/m 31 # 17 926 18 451 18 604 2 # 18 181 18 552 18 836 3 # 17 975 18 437 18 787 4 # 17 752 18 133 18 341 5 # 18 253 18 549 18 724 6 # 18 308 18 582 18 602 7 # 16 956 17 563 17 671 从 表 4中可看出,在抽采3个月后,从第4个月开始累计抽采量急剧下降,抽采量增加不多,到第5个月增加量已经不明显。与 表 3原设计方案对比,压裂后单孔累计抽采量,在第3个月已经与原始未压裂的6个月单孔累计抽采量持平,甚至总量略有提升,抽采效果明显。为保障抽采效果,压裂后对煤层的抽采周期应维持在至少4个月。

压裂抽采4个月后,在2 #压裂抽采孔两侧间隔2.5 m及5.0 m位置布置2个取样钻孔(深30 m),对取样总长度不小于40 cm的煤样进行采集,共制取5组样品,从采样到装入煤样罐密封的时间不超过10 min。依据GB/T 23250—2009《煤层瓦斯含量井下直接测定方法(DGC瓦斯含量测定)》,对煤层抽采的残存瓦斯含量进行测定。压裂抽采4个月后相对瓦斯含量测试数据见 表 5。

表 5 压裂抽采4个月后相对瓦斯含量数据钻孔位置 煤样编号 压裂抽采后相对瓦斯

含量/(m 3·t -1)原始相对瓦斯

含量/(m 3·t -1)1 #煤 2.63 10.85 2.5 m位置 2 #煤 2.58 3 #煤 2.67 4 #煤 2.59 5.0 m位置 5 #煤 2.62 6 #煤 2.71 平均 2.63 从 表 5中可看出,压裂抽采4个月后抽采瓦斯效果显著,相对瓦斯含量从10.85 m 3/t下降到了2.63 m 3/t。

试验结果表明,压裂后抽采周期大约缩短2~3个月,残存瓦斯含量也相对较低,抽采效果明显。

4. 结语

1) 五里堠煤矿2101工作面最大主应力为水平应力,其值为18.3 MPa,方向角为N31.65°E;中间主应力为垂直应力。压裂裂缝形态以垂直裂缝为主,方向角为N31.65°E。

2) 钻孔起裂压力为25~29 MPa,压裂有效影响半径为5~8 m。与原有抽采孔密度相比,压裂钻孔密度为原有的1/2,单位距离内钻孔施工量可缩减一半。

3) 与传统本煤层直接抽采工艺相比,现有压裂抽采瓦斯工艺可缩短抽采工期近3个月,且瓦斯含量可降低至2.63 m 3/t,压裂抽采效果显著。

4) 新的压裂抽采工艺不仅大大缩减了钻孔工程量,且显著缩短了瓦斯抽采工期,降低了工人的劳动强度,缩短了回采周期,可显著提高煤矿经济效益。该工艺对掘进工作面的快速掘进施工亦有重要的借鉴意义。

-

表 1 1号测孔的地应力测试数据

应力类别 应力/MPa 方向角/(°) 倾角/(°) 最大水平应力 σ 1 18.3 N31.65E 11.54 垂直应力 σ 2 11.7 N214.95E 82.57 最小水平应力 σ 3 10.2 N121.32E 15.51 表 2 观测孔含水率测试数据

钻孔

编号间距/

m30 m试样

含水率/%50 m试样

含水率/%70 m试样

含水率/%90 m试样

含水率/%1 # 3 6.8 7.3 6.7 7.1 2 # 5 5.7 6.2 6.1 6.3 3 # 8 4.3 3.7 4.4 4.5 4 # 10 3.2 3.0 3.5 3.3 5 # 12 2.8 2.6 3.3 2.2 表 3 原设计抽采钻孔逐月累计抽采瓦斯数据汇总

抽采时间/月 抽采瓦斯总量 Q t/m 3 5 17 452 6 17 813 7 18 004 表 4 压裂抽采钻孔逐月累计抽采数据汇总

抽采孔

编号3个月累计

抽采量/m 34个月累计

抽采量/m 35个月累计

抽采量/m 31 # 17 926 18 451 18 604 2 # 18 181 18 552 18 836 3 # 17 975 18 437 18 787 4 # 17 752 18 133 18 341 5 # 18 253 18 549 18 724 6 # 18 308 18 582 18 602 7 # 16 956 17 563 17 671 表 5 压裂抽采4个月后相对瓦斯含量数据

钻孔位置 煤样编号 压裂抽采后相对瓦斯

含量/(m 3·t -1)原始相对瓦斯

含量/(m 3·t -1)1 #煤 2.63 10.85 2.5 m位置 2 #煤 2.58 3 #煤 2.67 4 #煤 2.59 5.0 m位置 5 #煤 2.62 6 #煤 2.71 平均 2.63 -

[1] 孙庆刚. 中国煤矿瓦斯灾害现状及防治对策研究[J]. 中国煤炭, 2014, 40(3): 116-119. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGME201403032.htm [2] 邓林峰, 杨洋, 郑春山. 新集二矿地应力实测分析及其对瓦斯抽采的影响研究[J]. 煤炭技术, 2021, 40(10): 120-124. https://www.cnki.com.cn/Article/CJFDTOTAL-MTJS202110029.htm [3] 苏现波, 宋金星, 郭红玉, 等. 煤矿瓦斯抽采增产机制及关键技术[J]. 煤炭科学技术, 2020, 48(12): 1-30. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ202012001.htm [4] 刘震, 王文迪, 陈旦旦. 瓦斯抽采顺层钻孔封孔参数数值计算分析[J]. 矿业研究与开发, 2020, 40(12): 100-105. https://www.cnki.com.cn/Article/CJFDTOTAL-KYYK202012020.htm [5] 黄炳香, 陈树亮, 程庆迎. 煤层压裂开采与治理区域瓦斯的基本问题[J]. 煤炭学报, 2016, 41(1): 128-137. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201601019.htm [6] 任培良, 李宗泽, 杜培超. 孟津煤矿抽采钻孔封孔工艺参数优化试验研究[J]. 矿业研究与开发, 2020, 40(7): 54-57. https://www.cnki.com.cn/Article/CJFDTOTAL-KYYK202007011.htm [7] 陈龙, 龚选平, 成小雨, 等. 低瓦斯高强度开采综放工作面卸压瓦斯抽采关键技术[J]. 西安科技大学学报, 2021, 41(5): 815-824. https://www.cnki.com.cn/Article/CJFDTOTAL-XKXB202105009.htm [8] 杨百舸, 张军胜, 令狐建设, 等. 突出煤层CO 2气相压裂高效抽采防突掘进技术[J]. 煤田地质与勘探, 2021, 49(3): 85-94. https://www.cnki.com.cn/Article/CJFDTOTAL-MDKT202103011.htm [9] 赵阳升, 杨栋, 胡耀青, 等. 低渗透煤储层煤层气开采有效技术途径的研究[J]. 煤炭学报, 2001, 26(5): 455-458. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB200105001.htm [10] 袁志刚, 任梅清, 沈永红, 等. 穿层钻孔煤巷条带水力压裂防突技术及应用[J]. 重庆大学学报, 2016, 39(1): 72-78. https://www.cnki.com.cn/Article/CJFDTOTAL-FIVE201601010.htm [11] 孟雅, 李治平, 唐书恒, 等. 中、高阶煤样甲烷吸附应变及渗透性实验分析[J]. 煤炭学报, 2021, 46(6): 1915-1924. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB202106023.htm [12] LIU Ang, LIU Shimin, WANG Gang, et al. Modeling of coal matrix apparent strains for sorbing gases using a transversely isotropic approach[J]. Rock Mechanics and Rock Engineering, 2020, 53: 4163-4181.

[13] 冯彦军, 康红普. 水力压裂起裂与扩展分析[J]. 岩石力学与工程学报, 2013, 32(增刊2): 3169-3179. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX2013S2025.htm [14] 张群, 葛春贵, 李伟, 等. 碎软低渗煤层顶板水平井分段压裂煤层气高效抽采模式[J]. 煤炭学报, 2018, 43(1): 150-159. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201801019.htm [15] 徐刚, 彭苏萍, 邓绪彪. 煤层气井水力压裂压力曲线分析模型及应用[J]. 中国矿业大学学报, 2011, 40(2): 172-177. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKD201102003.htm [16] GIDLEY J L, HOLDITCH S A, NIERODE D E, et al. Recent advances in hydraulic fracture[J]. Society Petroleum Engineering Monograph, 1989: 452.

[17] MURDONCH L C, SLACK W W. Forms of hydraulic fractures in shallow fine-grained formations[J]. Journal of Geotechnical and Geoenvironment Engineering, 2002, 128(6): 479-487.

[18] 邓广哲, 王世斌, 黄炳香. 煤岩水压裂缝扩展行为特性研究[J]. 岩石力学与工程学报, 2004, 23(20): 3489-3493. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX200420021.htm [19] 黄炳香, 程庆迎, 刘长友. 裂隙水压力对煤岩体细观结构破坏分析[J]. 湖南科技大学学报, 2009, 24(1): 1-4. https://www.cnki.com.cn/Article/CJFDTOTAL-XTKY200901002.htm [20] 雷毅. 松软煤层井下水力压裂致裂机理及应用研究[D]. 北京: 煤炭科学研究总院, 2014. [21] 程远方, 徐太双, 吴百烈, 等. 煤岩水力压裂裂缝形态实验研究[J]. 天然气地球科学, 2013, 24(1): 134-137. https://www.cnki.com.cn/Article/CJFDTOTAL-TDKX201301019.htm [22] WU P F, LIANG W G, LI Z G, et al. Investigations on mechanical properties and crack propagation characteristics of coal and sandy mudstone using three experimental methods[J]. Rock Mech Rock Eng, 2017, 50(1): 215-223.

[23] 李登华, 高煖, 刘卓亚, 等. 中美煤层气资源分布特征和开发现状对比及启示[J]. 煤炭科学技术, 2018, 46(1): 252-261. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201801036.htm

下载:

下载: